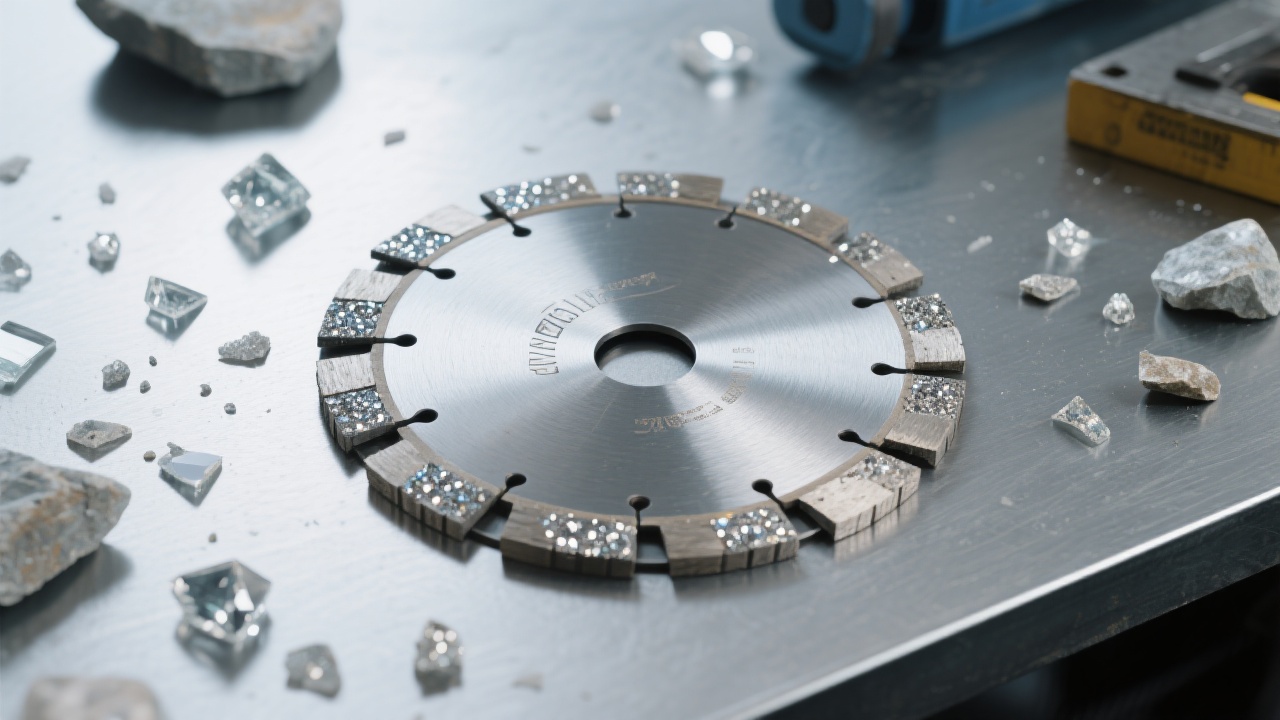

For industrial cutting professionals seeking precision, durability, and performance consistency, the 400H brazed diamond saw blade from Henan Yode Superhard Materials Tools Co., Ltd. represents a significant leap forward in abrasive tool technology. Unlike traditional welding methods, this blade leverages advanced brazing techniques that reduce thermal stress by up to 40%, resulting in longer service life and reduced downtime.

Our proprietary process ensures an average diamond particle density of 35–45 carats per square inch across the cutting edge—far exceeding industry standards (typically 25–30 carats/in²). This uniformity minimizes uneven wear and prevents premature blade failure during high-load operations like granite or concrete cutting.

| Performance Metric | Standard Blade | 400H Brazed Blade |

|---|---|---|

| Cutting Speed (m/min) | 18–22 | 28–34 |

| Tool Life (hours) | 8–12 | 18–25 |

| Heat Dissipation Efficiency | Moderate | High (with integrated cooling channels) |

The unique heat-dissipating structure—featuring micro-channel grooves along the blade body—has been validated through finite element analysis (FEA) simulations. In real-world tests under continuous operation at 60°C ambient temperature, our blades maintained stable surface temperatures below 120°C, while standard counterparts often exceeded 150°C, leading to accelerated diamond degradation.

These innovations are backed by ISO 9001:2015 certification, ensuring every batch meets rigorous quality control benchmarks—from raw material sourcing to final inspection. Over 97% of customer feedback cites improved reliability and fewer rework cycles as key benefits.

To extend blade life and maintain optimal cutting efficiency:

Whether you're managing a construction site, manufacturing facility, or stone processing plant, adopting these practices can lead to measurable gains in productivity and cost savings over time.

Ready to upgrade your cutting tools? Get a free technical brochure + access to our certified engineers for customized support.

Download Technical Guide Now →