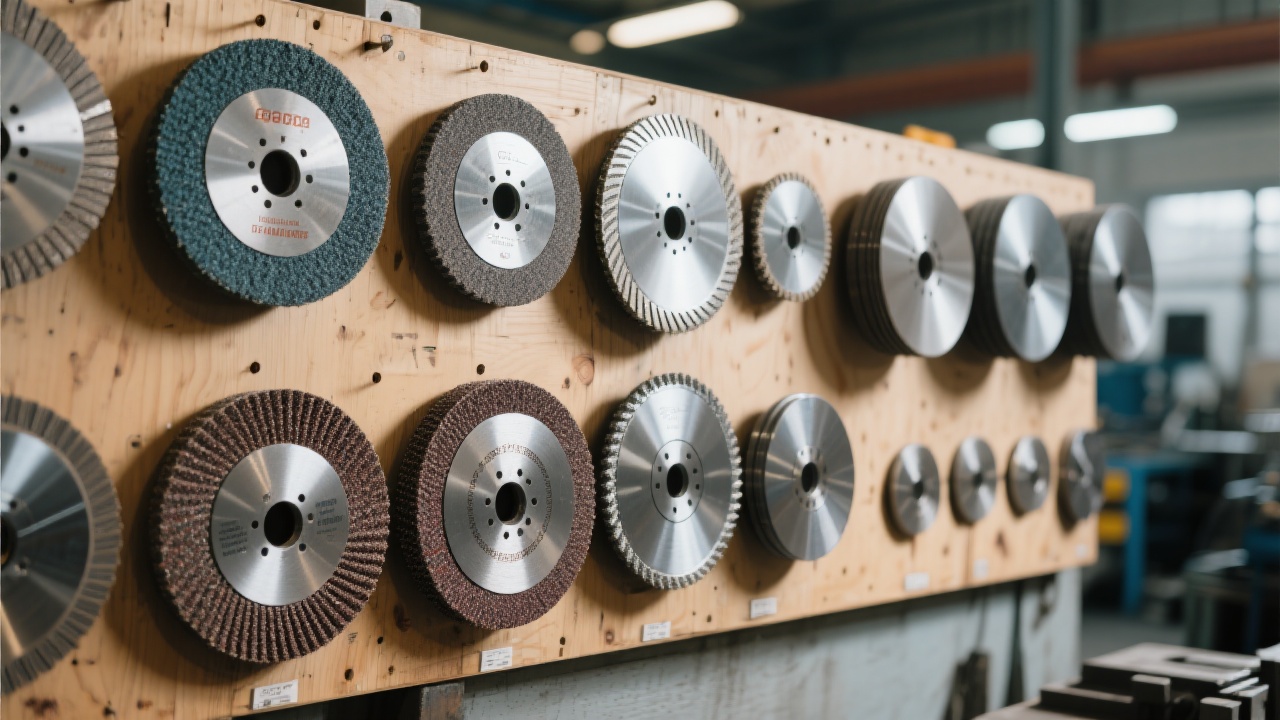

In the dynamic landscape of modern manufacturing, customized diamond tools have emerged as a game - changer for industries such as automotive parts, aerospace components, and high - end stone processing. UHD Superhard Materials Tools Co., Ltd. has been at the forefront of providing tailored solutions in this field, and this article delves into the key factors that contribute to the success of their customized diamond tools.

UHD starts by conducting in - depth customer requirement analysis. For example, in the automotive parts industry, a major client was facing challenges in achieving high - precision machining of engine components. UHD's team worked closely with the client to understand their specific needs. Through this process, they found that about 80% of the client's quality issues were related to inaccurate geometric measurements and improper tool design.

To address these issues, UHD adopted a scientific approach. They used advanced measurement technologies to accurately measure the geometric features of the workpieces. By doing so, they were able to reduce measurement errors from an average of 0.05mm to less than 0.01mm, significantly improving the overall machining accuracy.

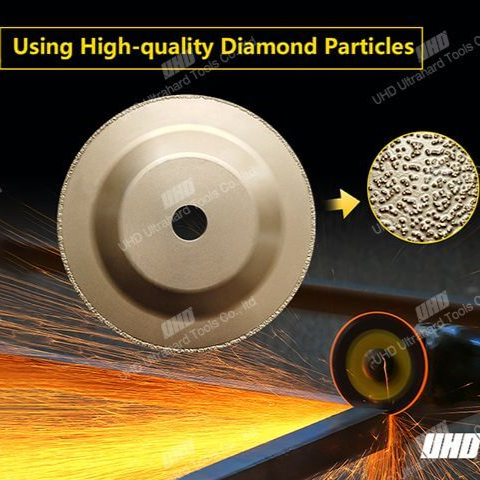

Several key technical aspects play a crucial role in the design and production of customized diamond tools. One of them is size tolerance control. In the aerospace industry, where components often have strict size requirements, UHD's tools can achieve a size tolerance of ±0.005mm. This high - precision control is achieved through a combination of advanced manufacturing processes and real - time quality monitoring systems.

Another important aspect is the design of the chip flutes. Proper chip flute design can improve the chip evacuation efficiency, reducing the risk of chip clogging and improving the surface finish of the workpiece. For example, in high - end stone processing, UHD's optimized chip flute design has increased the machining efficiency by up to 30% compared to traditional tools.

Thermal stability treatment is also a critical factor. High - speed machining generates a large amount of heat, which can affect the tool's performance and lifespan. UHD's thermal stability treatment can ensure that the tool maintains its hardness and performance even at temperatures up to 800°C, extending the tool's service life by about 50%.

Let's take a look at some real - world case studies. A client in the automotive industry was using standard diamond tools, but they were experiencing frequent tool breakage and low machining efficiency. After UHD provided a customized solution, the client saw a 40% reduction in tool replacement frequency and a 25% increase in overall machining efficiency.

Based on customer feedback, UHD continuously iterates its products. They analyze the data from the production site, such as tool wear rate, machining accuracy, and surface finish, to identify areas for improvement. Through this process, they have been able to reduce the comprehensive machining cost for their customers by an average of 20%.

UHD's customized diamond tools have proven to be a reliable solution for multiple industries, enabling manufacturers to achieve high - precision machining and gain a competitive edge. With continuous technological innovation and a focus on customer needs, UHD is well - positioned to lead the market in the field of customized diamond tools.

If you are looking for customized diamond tool solutions to improve your machining efficiency and reduce costs, don't hesitate to contact UHD today. Let UHD's expertise and experience help you achieve your manufacturing goals.