In the high-stakes industrial cutting sector, durability and performance of cutting tools directly affect productivity and operational costs. The 400H Brazed Diamond Saw Blade, developed by Henan Youde Superhard Materials Tools Co., Ltd., introduces a pioneering approach to thermal dissipation through its structural design. Leveraging an advanced bonding technology combined with optimized diamond particle distribution, this saw blade excels in high-temperature cutting environments, maintaining blade integrity and extending service life.

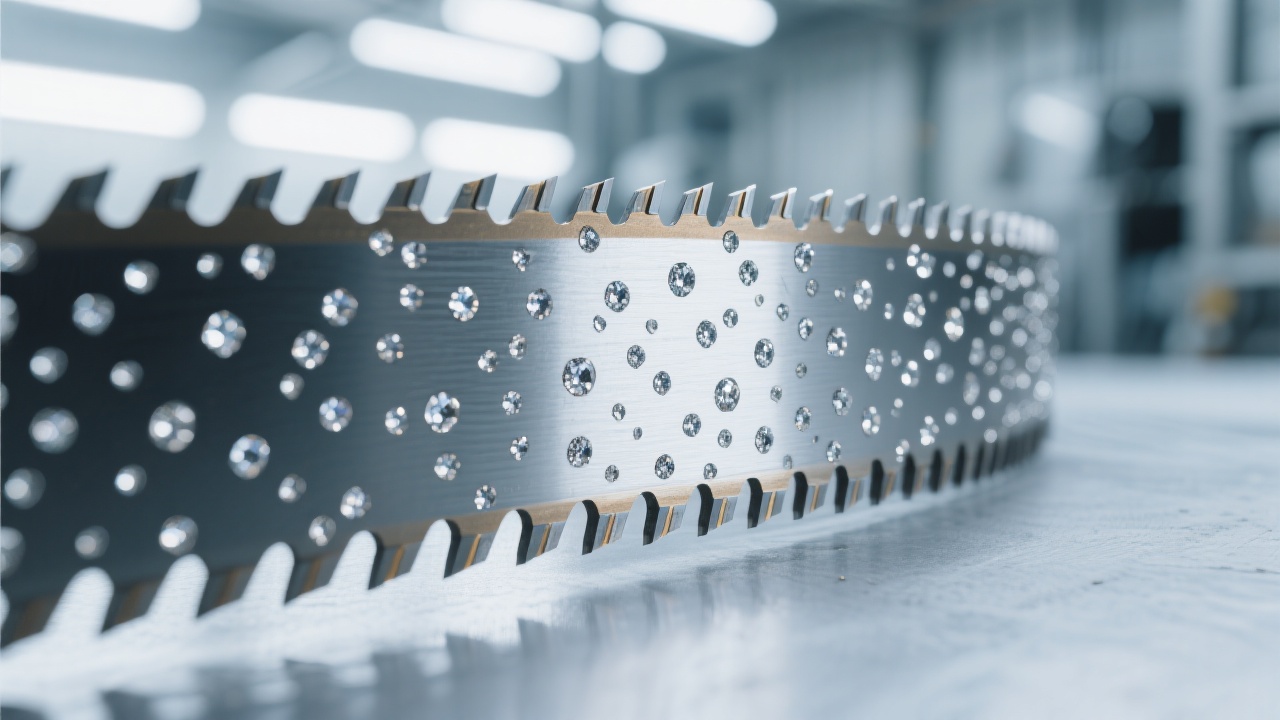

Central to the 400H’s outstanding performance is its uniformly distributed synthetic diamond grit embedded via an enhanced brazing process. This process improves the bond strength between the diamond particles and the saw blade substrate by approximately 30% compared to conventional methods, effectively preventing premature abrasive wear and diamond dislodgment.

The diamond grain size and concentration are meticulously calibrated; the blade incorporates ultra-fine 60/80 mesh diamonds evenly dispersed with a 25% volumetric content, balancing cutting aggressiveness and wear resistance. This precise dispersion mitigates micro-fractures during intense cutting operations, thus optimizing cutting stability.

High temperatures during cutting accelerate tool degradation, particularly in hard materials. The 400H blade counters this challenge via a unique multi-channel heat dissipation architecture. Strategically placed cooling fins and vented slots increase convective airflow around the blade surface, lowering operating temperatures by as much as 20°C under continuous load conditions.

This thermal management innovation reduces thermal expansion and warping, which are common failure modes in prolonged, high-intensity cutting. Consequently, the 400H sustains consistent cutting speed and accuracy, significantly reducing downtime linked with blade replacement.

Practical experience has shown that the 400H blade's performance peaks when employed within cutting environments that leverage its thermal dissipation traits. For instance, cutting abrasive and composite materials at speeds between 35-50 m/s with coolant application results in a 15-25% increase in blade lifespan, as observed in multiple industrial case studies.

Proper maintenance protocols are vital. Operators are advised to routinely inspect the blade for uniform diamond exposure and clean cooling slots from debris to maintain maximum heat transfer efficiency. Using the blade within the manufacturer’s recommended RPM range enhances stability and minimizes the risk of mechanical failure.

The 400H brazed diamond saw blade operates under a stringent ISO 9001 quality management system, ensuring every production batch meets exacting standards for material composition, bonding integrity, and structural design. This adherence guarantees predictable and repeatable blade performance, which is critical for industrial customers requiring process consistency.

Quality audits include fatigue resistance testing, thermal performance validation via infrared thermography, and abrasive wear analysis, supporting confidence in the 400H blade for precision cutting applications in sectors such as construction, stone fabrication, and aerospace tooling.

Discover how the advanced thermal dissipation design and reinforced bonding technology of the 400H series can revolutionize your cutting applications. Whether addressing demanding industrial tasks or seeking enhanced tool longevity, this saw blade sets a new standard for precision and durability.

Explore 400H Saw Blade Specifications & Request Technical Support