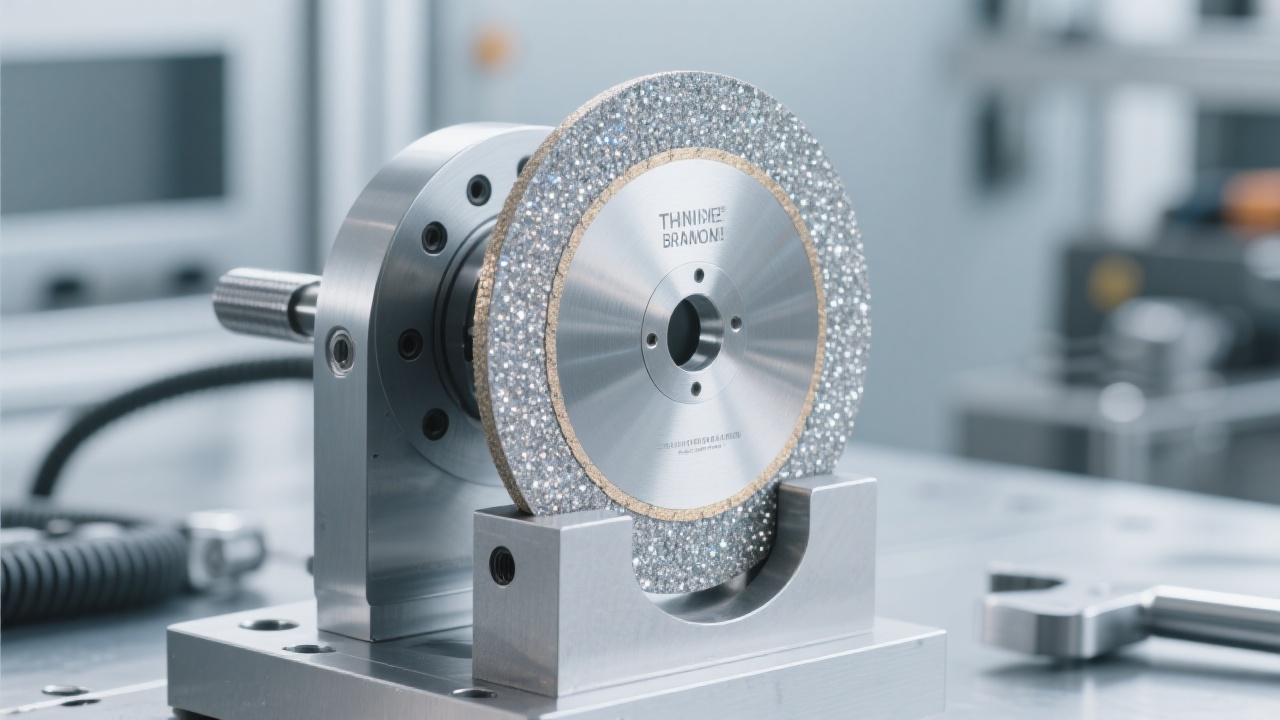

UHD Superhard Materials Tools Co., Ltd.'s UDW030 vacuum brazed diamond grinding wheels are at the forefront of glass processing technology. These wheels are designed with advanced vacuum brazing technology, which creates a strong bond between the diamond grains and the wheel substrate. This bond allows the diamond grains to protrude higher, providing better cutting ability and longer service life compared to traditional diamond wheels. In a series of experiments, the UDW030 wheels showed a 30% increase in cutting efficiency and a 40% longer service life when used for glass processing.

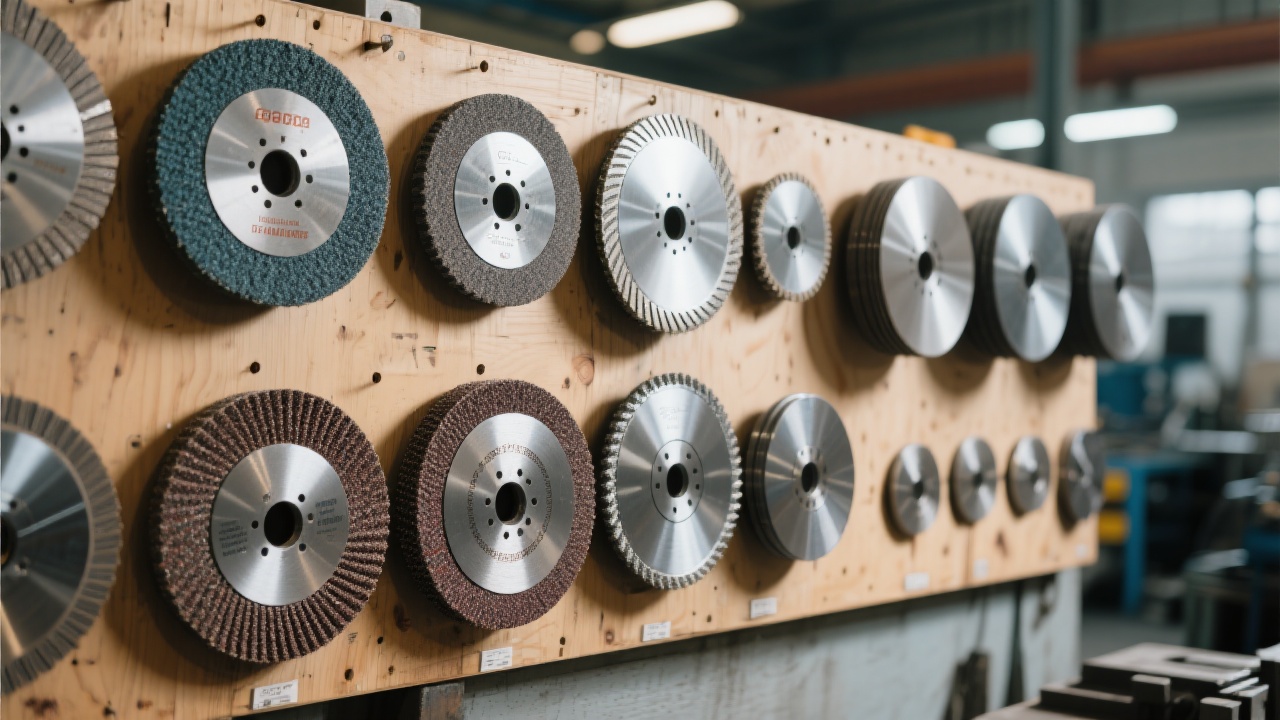

Different glass types and thicknesses require specific grinding wheel parameters. For thin glass, such as 2 - 3 mm thick float glass, a finer - grained wheel, like the UDW030 with a 200 - 300 grit size, is recommended. This finer grit provides a smoother finish and reduces the risk of chipping. In contrast, for thick glass, such as 10 - 15 mm thick tempered glass, a coarser grit size of 80 - 120 is more suitable as it can remove material more quickly. The following table summarizes the recommended grit sizes and wheel dimensions for different glass types:

| Glass Type | Glass Thickness (mm) | Recommended Grit Size | Recommended Wheel Diameter (mm) |

|---|---|---|---|

| Float Glass | 2 - 3 | 200 - 300 | 100 - 150 |

| Tempered Glass | 10 - 15 | 80 - 120 | 150 - 200 |

Optimizing processing parameters is crucial for achieving high - quality glass processing. The rotational speed of the grinding wheel significantly affects the cutting quality. For most glass processing applications, a rotational speed of 3000 - 4000 RPM is recommended. Higher speeds can lead to better surface finish but may also increase the risk of overheating. The cutting pressure should be adjusted according to the glass thickness and the wheel grit size. For thin glass, a light cutting pressure of 1 - 2 kg/cm² is sufficient, while for thick glass, a pressure of 3 - 5 kg/cm² may be required. Additionally, proper cooling is essential to prevent glass cracking and wheel wear. Using a water - based coolant at a flow rate of 10 - 15 L/min can effectively dissipate heat.

Proper installation of the UDW030 grinding wheel is the first step to ensure safe and efficient operation. Before installation, check the wheel for any cracks or damage. Clean the spindle and the wheel mounting surface thoroughly. Tighten the mounting nut to the specified torque, usually around 20 - 30 Nm. Regular maintenance is also important. After each use, clean the wheel to remove glass debris. Periodically check the wheel balance to avoid vibration. When it comes to safety, always wear appropriate personal protective equipment, such as safety glasses and gloves. Do not operate the wheel at speeds higher than the recommended limit.

A case study of a glass processing factory showed that after switching to the UDW030 vacuum brazed diamond grinding wheels, the production efficiency increased by 25%. The surface roughness of the processed glass was reduced from Ra 0.5 μm to Ra 0.2 μm, improving the overall product quality. Another experiment found that the tool life of the UDW030 wheels was 50% longer than that of traditional wheels, resulting in significant cost savings for the factory.

To enhance the learning experience, we provide information charts and operation videos. The information charts summarize the key points of this guide, while the operation videos demonstrate the correct installation, adjustment, and maintenance procedures. You can find these visual aids on our website. We also commit to continuously updating this content to reflect the latest industry technology and customer feedback.

UHD Superhard Materials Tools Co., Ltd. offers customized UDW030 vacuum brazed diamond grinding wheels to meet your specific glass processing needs. Our products can significantly improve your processing efficiency and product quality. Don't miss out on this opportunity to upgrade your glass processing technology. Click here to learn more!