Precision and durability are the twin pillars of efficient industrial cutting, particularly when working with abrasive and dense materials such as concrete and granite. Brazed diamond saw blades stand out as a preferred tool for professionals aiming to balance cut quality, operational safety, and blade longevity. This article offers a deep dive into the manufacturing craftsmanship behind these blades, elucidates thermal management innovations, and highlights critical quality certifications—including ISO 9001—that underpin product reliability.

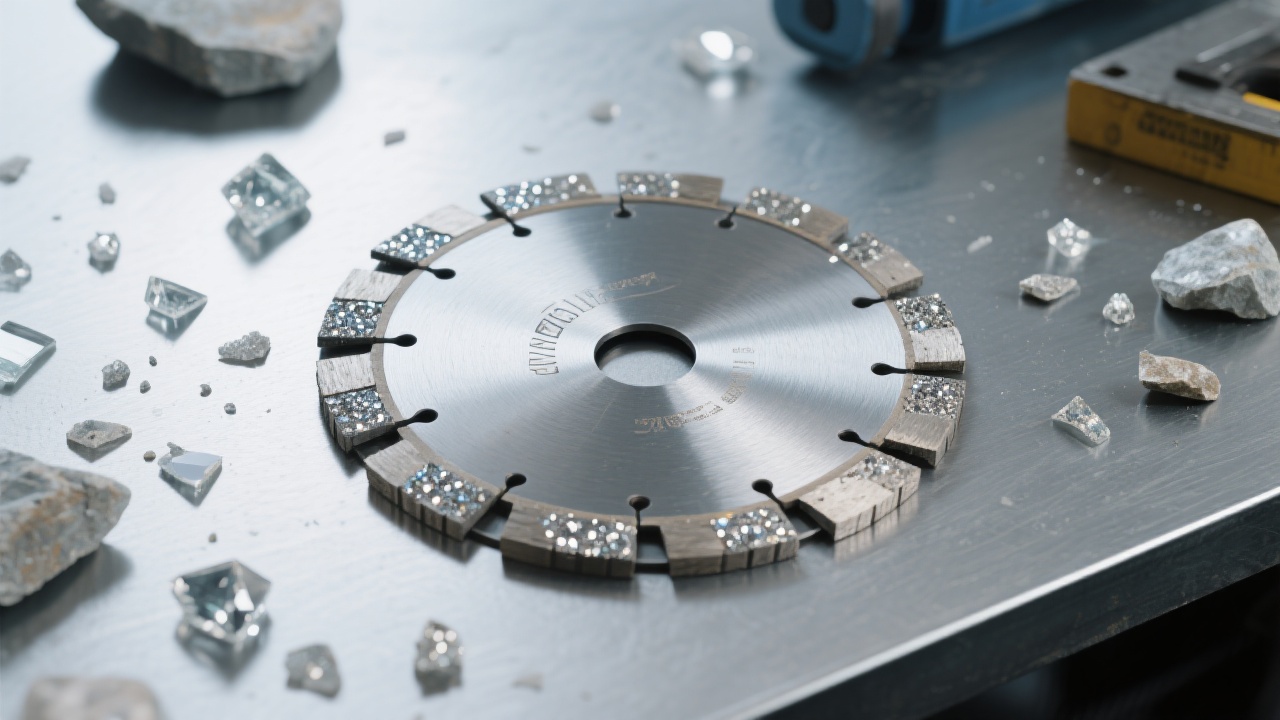

At the core of a premium diamond saw blade lies the brazing technique, which directly influences cutting efficiency and blade lifespan. The process involves metallurgically bonding diamond particles to the steel base using a high-temperature filler metal. Precision in distributing these diamond grains uniformly ensures each cutting edge engages material consistently, minimizing uneven wear.

Recent advancements incorporate micro-alloying in filler metals that significantly enhance bond strength, reducing diamond loss rates under high-stress cutting environments by as much as 15-20%. This improvement translates to longer intervals between blade replacements and a more stable cut depth, crucial for industrial applications with tight tolerances.

Excessive heat generated during cutting accelerates wear and can cause micro-fractures in both blade and material. To counteract this, advanced saw blades feature optimized scatter patterns and proprietary ventilation grooves enhancing airflow across the cutting surface.

Empirical data collected in industrial testing environments reveal that these enhanced heat dissipation structures can reduce blade temperature by up to 25%, significantly extending blade life by curtailing thermal fatigue. For users, this innovation ensures smoother operation under continuous load conditions and lowers the risk of blade deformation.

Quality management informed by the ISO 9001 standard guarantees that each production batch undergoes rigorous validation. This comprehensive framework covers raw material sourcing, process control, performance testing, and traceability, delivering stable product characteristics batch after batch.

“Incorporating ISO 9001 certified blades consistently reduced downtime and maintenance costs in our cutting operations by 18% over 12 months,” reported a leading construction materials supplier.

For procurement specialists, prioritizing ISO-certified products minimizes risk and affirms commitment to safety and industrial standards.

The choice between dry and wet cutting profoundly affects saw blade wear patterns and operational parameters. Wet cutting reduces dust emissions and cools the blade, which is advantageous for materials prone to micro-cracking under heat, like granite. Conversely, dry cutting offers speed and convenience where water application is impractical but demands special blade heat management.

| Feature | Wet Cutting | Dry Cutting |

|---|---|---|

| Operating Temperature | Lower (~30-40% under ambient) | Higher, requires ventilation features |

| Blade Lifespan | Up to 20% longer | Faster wear, depending on material hardness |

| Dust Emission | Minimal | High, requires PPE |

To maximize cutting precision and blade lifespan, operators should strictly adhere to manufacturer-recommended cutting speeds—typically between 20 to 35 m/s—and maintain consistent feed rates. Routine cleaning to remove accumulated debris and inspections for segment wear or cracks are essential preventive steps. Lubrication is unnecessary for brazed blades but ensuring adequate cooling (via water or air) prevents thermal stress.

The Yude Superhard 400H brazed diamond saw blade uniquely combines advanced brazing metallurgy with proprietary aerodynamic design to deliver superior cutting accuracy and extended service life. Its ISO 9001 certified manufacturing assures product consistency, while its enhanced heat dissipation channels provide outstanding reliability across dry and wet cutting environments.

Industrial buyers and technical specialists striving for a cutting tool that consistently meets aggressive production demands and safety standards will find the 400H an invaluable asset.

“Switching to Yude 400H blades resulted in a 30% improvement in cutting cycle times on granite slabs without compromising segment integrity,” states a senior project manager from a top construction firm.