In the field of hard material cutting, diamond saw blades are widely used due to their excellent hardness and cutting performance. However, the lifespan of diamond saw blades has always been a concern for industrial customers and technicians. This article focuses on Henan Youde Superhard Material Tools Co., Ltd.'s 400H brazed diamond saw blade, and explores how to extend the saw blade's lifespan and improve cutting efficiency through optimized cooling methods by comparing dry and wet cutting.

Dry cutting is a cooling method without the use of external cooling liquids. During the cutting process, the heat generated is mainly dissipated through the saw blade itself and the surrounding air. The advantage of dry cutting is that it is simple and convenient, and there is no need to consider issues such as coolant treatment. However, the heat generated during cutting cannot be effectively dissipated, which may lead to an increase in the temperature of the saw blade, resulting in decreased wear - resistance and instability of the cutter head.

Wet cutting uses a coolant (usually water) to cool the saw blade during the cutting process. The coolant can absorb a large amount of heat, reduce the temperature of the saw blade, and at the same time flush away the chips generated during cutting. This can effectively improve the wear - resistance of the saw blade and the stability of the cutter head. However, wet cutting requires additional equipment for coolant supply and treatment, and there may be problems such as rusting of the equipment in a humid environment.

When cutting concrete, wet cutting is generally more suitable. Concrete cutting generates a large amount of dust, and wet cutting can not only cool the saw blade but also suppress dust. According to relevant data, when using wet cutting to cut concrete, the lifespan of the saw blade can be extended by about 30% compared with dry cutting, and the cutting efficiency can be increased by about 20%.

Granite is a very hard material, and the heat generated during cutting is relatively large. Wet cutting can effectively cool the saw blade and reduce the wear of the cutter head. In some large - scale granite processing plants, the use of wet cutting has increased the saw blade's cutting length by about 40% and improved the surface finish of the cut granite.

| Cutting Material | Cutting Method | Saw Blade Lifespan Extension | Cutting Efficiency Improvement |

|---|---|---|---|

| Concrete | Wet Cutting | About 30% | About 20% |

| Granite | Wet Cutting | About 40% | Improved surface finish |

A proper cooling method can keep the saw blade at a relatively low temperature, reducing the thermal wear of the diamond particles on the saw blade. For example, in wet cutting, the coolant can take away a large amount of heat, so that the diamond particles can maintain their hardness and cutting performance for a longer time, thereby improving the wear - resistance of the saw blade.

High temperatures can cause the cutter head to expand and contract, which may lead to the loosening of the cutter head and affect the cutting accuracy. By optimizing the cooling method, the temperature of the cutter head can be kept stable, ensuring the stability of the cutter head during the cutting process.

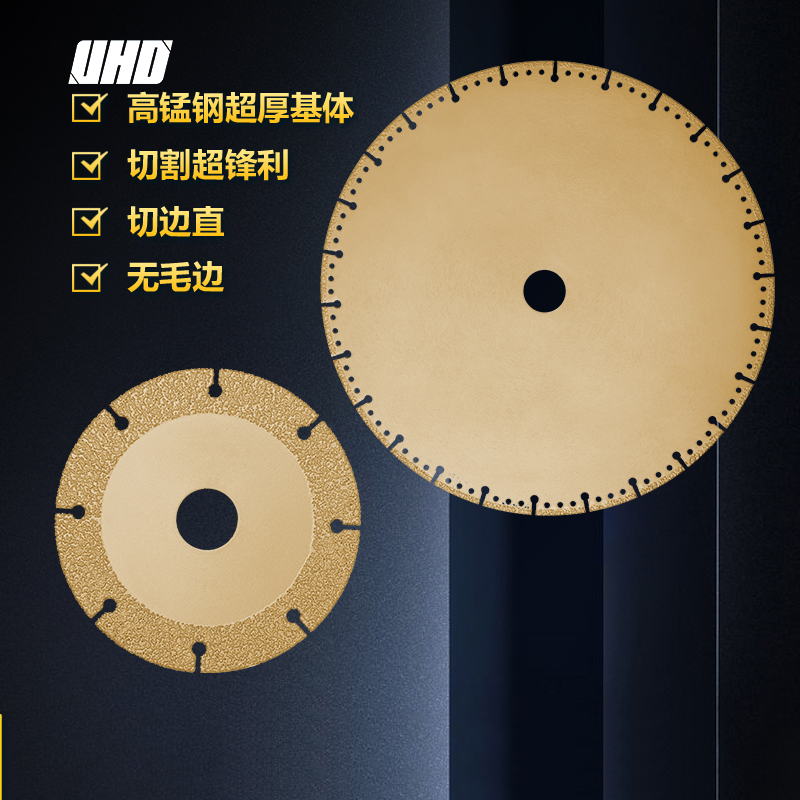

The 400H saw blade of Youde Superhard uses enhanced bonding technology, which can firmly bond the diamond particles to the saw blade substrate. In the cooling process, whether it is dry or wet cutting, this bonding technology can ensure that the diamond particles do not fall off easily, improving the overall performance of the saw blade.

The saw blade is designed with a special heat dissipation structure, which can increase the heat dissipation area and accelerate the heat dissipation speed. In dry cutting, this heat dissipation structure can effectively reduce the temperature of the saw blade; in wet cutting, it can also cooperate with the coolant to achieve better cooling results.

In a certain concrete cutting project, the initial use of dry cutting led to rapid wear of the saw blade and low cutting efficiency. After switching to wet cutting and adjusting the rotational speed and feed rate, the saw blade's lifespan was extended from the original 1000 linear meters to 1300 linear meters, and the cutting efficiency was increased by about 25%.

When using wet cutting, it is recommended to adjust the coolant flow rate according to the cutting material and cutting speed. Generally, for concrete cutting, the coolant flow rate can be controlled at about 10 - 15 liters per minute; for granite cutting, the flow rate can be increased to 15 - 20 liters per minute. At the same time, the rotational speed and feed rate also need to be adjusted reasonably. For example, when cutting hard materials, reducing the rotational speed and increasing the feed rate appropriately can improve the cutting efficiency and reduce the wear of the saw blade.

In conclusion, optimizing the cooling method is an effective way to extend the lifespan of diamond saw blades and improve cutting efficiency. By comparing dry and wet cutting, understanding the technical features of Youde Superhard 400H saw blade, and referring to construction cases and parameter adjustment suggestions, industrial customers and technicians can find a more suitable cooling solution. Do you have any questions about diamond saw blade cooling optimization? Feel free to share your thoughts. If you want to learn more about the Hard Material Cutting Parameter Comparison Table and technical support, welcome to visit Youde Superhard's technology column.