This article is tailored for industrial cutting technicians and procurement managers, aiming to provide an in - depth analysis of the key role and advantages of ISO 9001 certification in the quality management of brazed diamond saw blades.

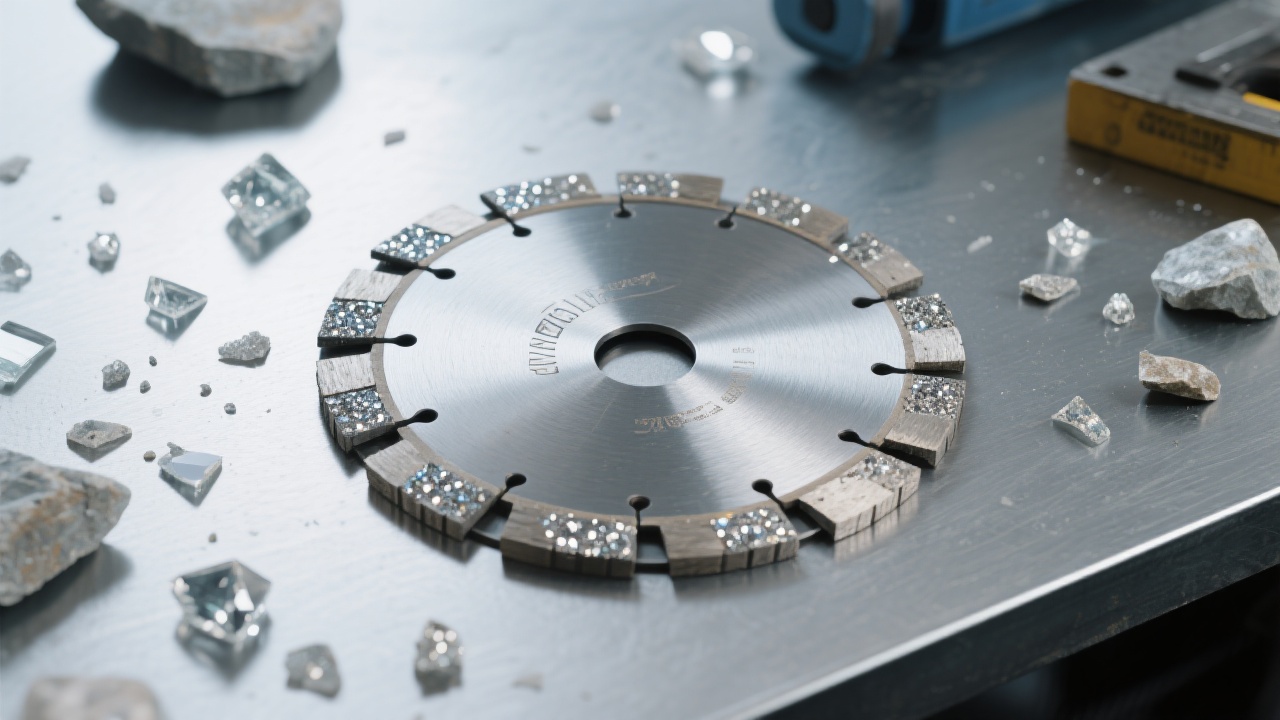

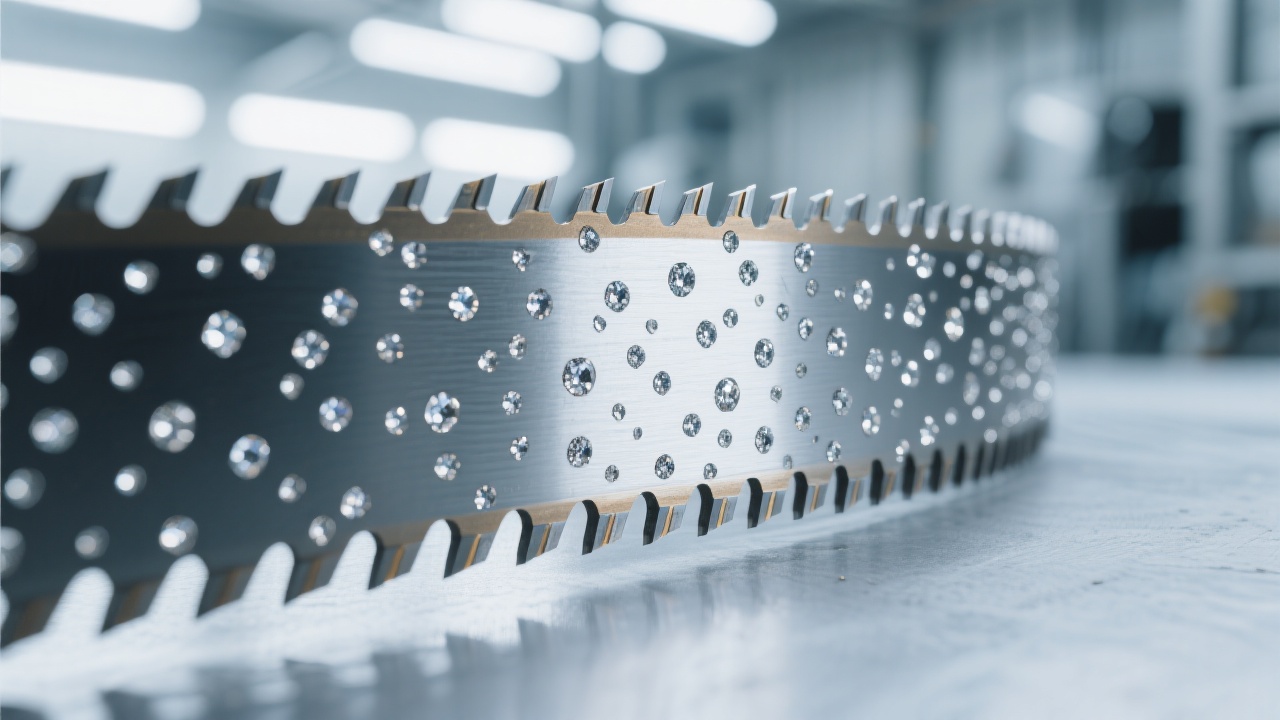

In the manufacturing of brazed diamond saw blades, the brazing process is of great significance. The uniform distribution of diamond particles is a fundamental factor affecting the performance of the saw blade. For example, in the Youde Superhard 400H saw blade, through advanced technology, the diamond particles are evenly distributed, which can ensure stable cutting performance during the cutting process. The application of enhanced bonding layer technology further strengthens the connection between the diamond particles and the substrate, improving the overall strength of the saw blade. According to relevant data, saw blades with enhanced bonding layer technology can increase the cutting efficiency by about 20% compared with ordinary saw blades.

The heat dissipation structure design is another key factor in the quality management of saw blades. In high - temperature working conditions, the heat generated during the cutting process can easily cause damage to the saw blade. The design concept of the heat dissipation structure in the Youde Superhard 400H saw blade can effectively reduce the temperature of the saw blade during operation. Studies have shown that this design can increase the service life of the saw blade in high - temperature working conditions by about 30%. This means that users can reduce the frequency of saw blade replacement and improve production efficiency.

There are significant differences in performance and stability between ordinary saw blades and ISO - certified saw blades. The following table shows the comparison results:

| Performance Indicators | Ordinary Saw Blades | ISO - Certified Saw Blades |

|---|---|---|

| Cutting Efficiency | Relatively low | Relatively high, about 20% higher than ordinary saw blades |

| Service Life | Shorter | Longer, especially in high - temperature working conditions, about 30% longer |

| Stability | Poor | Good, can reduce the risk of equipment downtime |

In a large - scale industrial cutting project, a company initially used ordinary saw blades, and the equipment downtime rate was as high as 15% due to saw blade problems. After switching to ISO - certified Youde Superhard 400H saw blades, the equipment downtime rate was reduced to less than 5%. This shows that the ISO 9001 quality management system can effectively reduce the risk of equipment downtime and improve production efficiency.

Products with ISO 9001 certification have high product consistency, which means that users can get the same high - quality products every time they purchase. In addition, the traceability of products allows users to clearly understand the production process and quality control details of the products. And the after - sales technical support can provide users with timely solutions to problems, which is very important for industrial users.

In conclusion, when choosing brazed diamond saw blades, users should not only focus on price or parameters, but also understand the quality control logic of the manufacturing end. By choosing ISO - certified saw blades, users can get more reliable products and better services. 立即获取免费技术手册或预约一对一锯片选型指导 (Get a free technical manual or book a one - on - one saw blade selection consultation immediately)