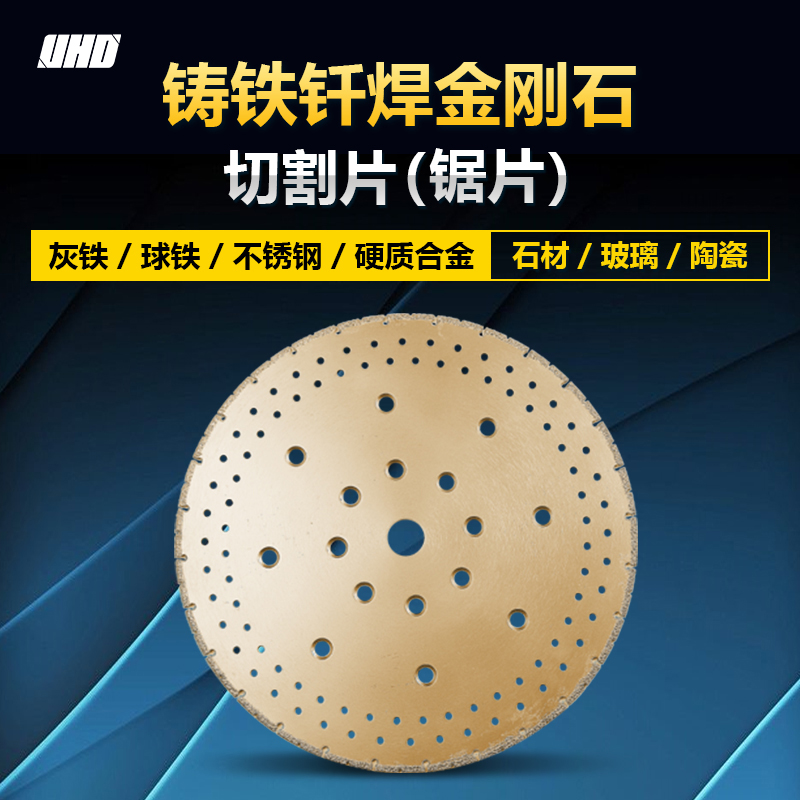

The 400H brazed diamond saw blade is a remarkable cutting tool that combines several advanced technologies. It features high - quality diamond particles, an alloy matrix, and a precision brazing process. The high - quality diamond particles are carefully selected for their hardness and abrasion resistance. These diamonds are firmly bonded to the alloy matrix through the precision brazing process, ensuring a strong and stable structure. This combination allows the saw blade to maintain its cutting performance even under high - stress conditions.

When it comes to cutting efficiency and lifespan, the 400H saw blade shows outstanding performance on various materials. In concrete cutting, compared to traditional saw blades, the 400H saw blade can increase the cutting speed by up to 30%. For example, in a standard concrete cutting project, a traditional saw blade might take 60 minutes to complete a certain length of cut, while the 400H saw blade can finish the same task in just 42 minutes.

On granite, the 400H saw blade also demonstrates excellent durability. Tests have shown that it can make up to 200 cuts before significant wear occurs, while a traditional saw blade may only be able to make 100 cuts. In the case of tile cutting, the precision of the 400H saw blade ensures clean and smooth cuts, reducing the number of broken tiles. It can cut up to 500 tiles with minimal chipping, compared to around 300 tiles for traditional saw blades.

In municipal infrastructure projects, the 400H saw blade has been widely used. For instance, in a large - scale road construction project, the saw blade was used to cut concrete barriers. Workers reported that the saw blade's low - vibration design made the operation more comfortable and safer. The saw blade's long lifespan also reduced the frequency of blade replacement, saving both time and labor costs.

In the stone processing industry, the 400H saw blade has become a preferred choice. A stone processing factory shared their experience: "Since we started using the 400H saw blade, our production efficiency has increased by 25%. The clean cuts also improve the quality of our finished products." In the decoration industry, the saw blade's ability to cut tiles precisely has made it a favorite among decorators.

One of the significant advantages of the 400H saw blade over traditional saw blades is its heat sink design. During the cutting process, a large amount of heat is generated. Traditional saw blades often suffer from overheating, which leads to rapid wear and reduced lifespan. The 400H saw blade's heat sink design effectively dissipates heat, reducing the temperature of the blade by up to 20%. This temperature reduction significantly extends the blade's lifespan. In a side - by - side comparison, a traditional saw blade without a heat sink design had to be replaced after 50 hours of continuous use, while the 400H saw blade could still operate effectively after 100 hours.

The concept of "durability is the key" in the 400H saw blade directly translates into cost savings and safety improvements for customers. With its long lifespan, customers can reduce the frequency of blade replacement, which means lower procurement costs. In addition, the low - vibration design and stable cutting performance of the 400H saw blade enhance the safety of the operation. Workers are less likely to be injured due to blade breakage or unstable cutting.

The 400H diamond saw blade is a reliable and cost - effective solution for cutting hard materials. It has been verified in more than 50 countries around the world, making it a globally applicable cutting tool. If you are looking for a high - performance saw blade for your construction or industrial projects, the 400H saw blade is definitely worth considering. Click here to learn more about how the 400H saw blade can meet your specific needs!