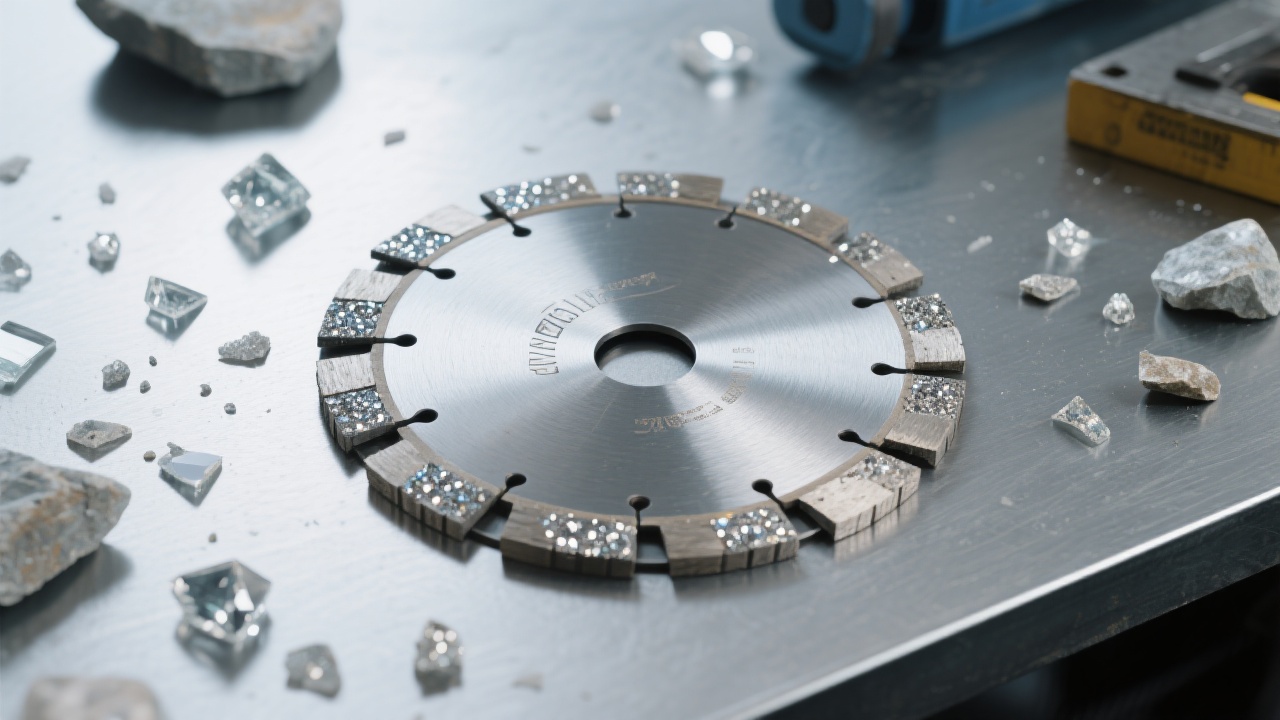

You're likely familiar with the challenges in industrial cutting. The right cutting tool can be a game - changer, and that's where the brazed diamond saw blade comes in. In the industrial arena, this tool is more than just a cutting device; it's a key factor in enhancing efficiency and reducing costs.

Brazed diamond saw blades offer distinct advantages. They are incredibly wear - resistant, making them a long - lasting choice for industrial cutting. Their ability to handle hard materials like concrete and granite is remarkable, providing stable and efficient cutting performance. This not only saves time but also reduces the need for frequent tool replacement, which is a significant cost - saver in the long run.

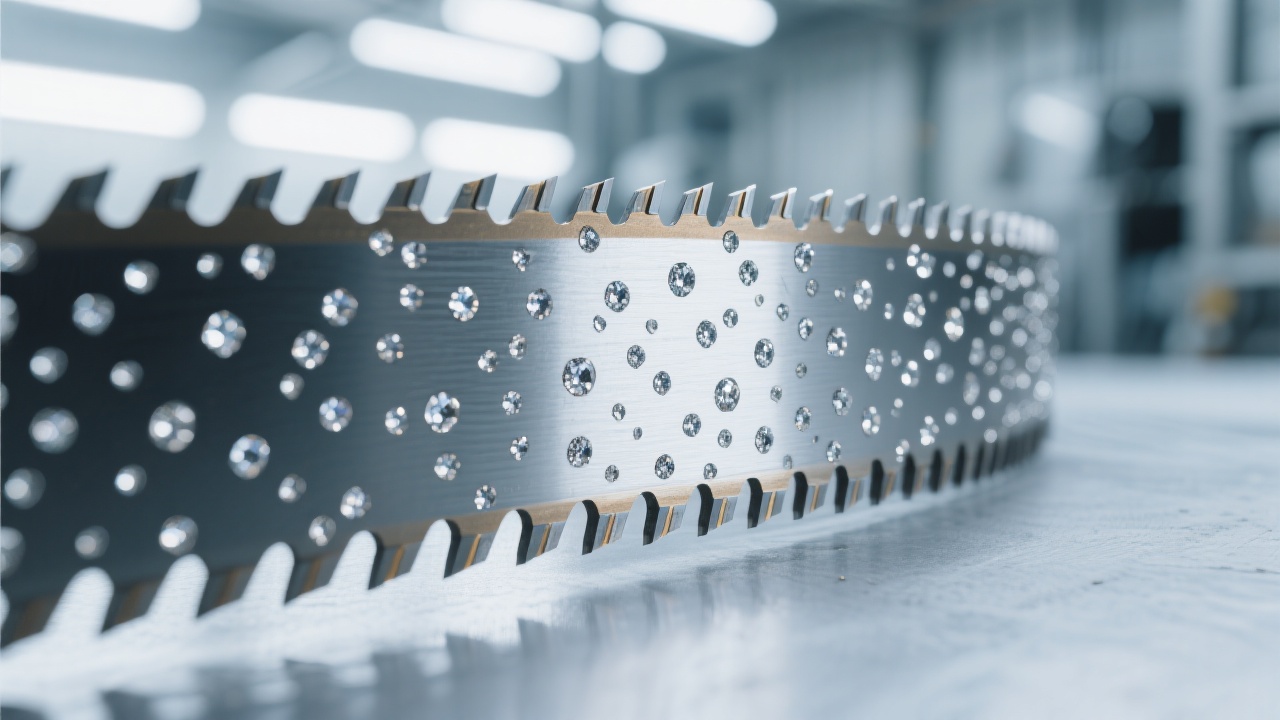

The uniform distribution of diamond particles is a cornerstone of the 400H saw blade's performance. When diamond particles are evenly spread, the cutting force is evenly distributed across the saw blade. This results in a smoother cut and reduces the risk of premature wear in specific areas. According to industry data, saw blades with uniform diamond particle distribution can increase cutting efficiency by up to 30% compared to those with uneven distribution.

The enhanced bonding technology ensures a strong connection between the diamond particles and the saw blade matrix. This prevents diamond particles from falling off during cutting, which is crucial for maintaining cutting performance. A well - bonded saw blade can withstand higher cutting forces and operate at higher speeds, leading to faster cutting times.

The unique heat dissipation structure design is another highlight. During cutting, a significant amount of heat is generated. If not properly dissipated, this heat can damage the saw blade and reduce its lifespan. The innovative heat dissipation design of the 400H saw blade allows for efficient heat transfer, keeping the saw blade at an optimal temperature.

Whether it's a dry or wet cutting environment, the brazed diamond saw blade performs admirably. In dry cutting, temperature control is crucial. You should limit the cutting speed to prevent overheating. A general rule of thumb is to keep the cutting speed below 50 m/s. In wet cutting, the water acts as a coolant and lubricant. However, you still need to ensure proper water flow to maintain the right temperature.

Regular maintenance is essential for extending the life of your saw blade. Clean the saw blade after each use to remove debris. When installing the saw blade, follow the manufacturer's guidelines carefully. Avoid common mistakes such as incorrect tightening, which can lead to uneven stress distribution and premature wear.

The product's ISO 9001 certification is a testament to its reliability. ISO 9001 is an internationally recognized quality management system standard. Products that meet this standard have undergone strict quality control processes, ensuring consistent performance and reliability. When you choose a brazed diamond saw blade with ISO 9001 certification, you're choosing a product that meets high - quality standards.

In real - world applications, the use of brazed diamond saw blades has led to significant efficiency improvements. For example, in a construction project where granite slabs need to be cut, using the 400H saw blade reduced the cutting time by 40% compared to traditional saw blades. This not only increased productivity but also reduced labor costs.

Now, we'd like to hear from you. Have you used brazed diamond saw blades in your industrial operations? What challenges have you faced? Leave your comments below.

Ready to enhance your industrial cutting efficiency? Contact our technical support team at Youde Superhard for a free technical manual.